There’s a rumour going around the internet discussion groups that my friend Kim White

has passed away. Well he checked his pulse tomorrow (he’s in Australia), everything is working

fine and he’s enjoying riding around on his BSA.

There’s a rumour going around the internet discussion groups that my friend Kim White

has passed away. Well he checked his pulse tomorrow (he’s in Australia), everything is working

fine and he’s enjoying riding around on his BSA.

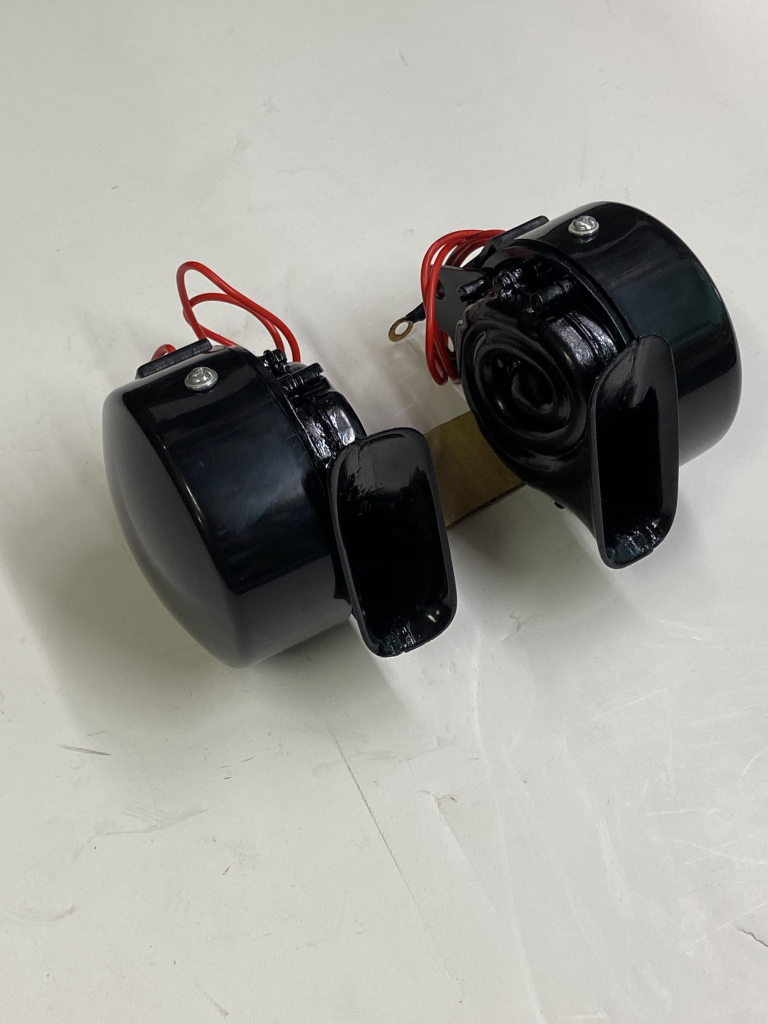

NEW MANUFACTURE, HI/LO TONES, EXCLUSIVELY FOR WALRIDGE MOTORS LIMITED.

Part No 60-1900/1

$325.00 PR CANADIAN ($243.75US at current rate of exchange)

Customer with 1970 Bonneville asked this question and was looking at getting better quality clutch plates.

“I’m planning to redo the clutch on my bike. It has the common problem of being very hard to disengage if the bike has been sitting but the biggest problem is the increase in drag and gear crunching when driving in traffic”

Here’s my reply. The basic principles apply to all bikes with multi plate clutches.

“The problems you have might go a bit deeper. As it is a 1970 you have to use the same oil in the primary case as in the motor so 20/50 is what you are probably using. Castrol “Go” is designed specifically for motorcycles. I remember when I bought my new T100SS in 1966 the handbook said to pull in the clutch lever and free off the plates before trying to start. However you are still having problems while riding. It may be that the grooves in the clutch centre and/or basket are worn -which would cause the plates to settle towards the grooves and make them drag when you pull in the lever. Worth looking at.”

Of course should also examine the plates to make sure they are all perfectly flat.

Customer says bike cuts out and dies on one cylinder.

This can’t be a problem with the electronic ignition. Suggest he swaps the plug leads over – if the problem goes to the other side it must be one of the following – HT Windings in the coil, plug lead or spark plug. If it stays on the same side it must be a mechanical or carburation problem with that cylinder.

A popular misconception is that the little pick up coils on the stator plate are connected individually to each cylinder, telling the plugs when to fire. They actually operate like a small alternator and it is the speed of the current waves it creates which dictate the advance curve and tells the coils when to fire.

The biggest challenge those of us in the business of supplying British motorcycle parts in the daily deluge of enquiries from people looking for help. One UK dealer says the number of enquiries has gone up 300% in the last couple of years and they have stopped answering them – they just don’t have the resources to deal with it. If you need help and advice with your project, join the relative owners’ club and hook up with an expert on your particular bike.

Probably 50% of the enquiries we receive relate to electrical issues. If you don’t understand voltage, ohms (resistance) and current (amps) and the relationship between them, please don’t call us, we will just waste each other’s time.

Every bike – and most other vehicles – has three aspects to its electrical system and each operates on its own, largely unrelated to the other two.

Something makes the electricity. Generator with control unit or alternator with rectifier and zener diode (or modern solid state rectifier/regulator).

Something stores the electricity – battery and or capacitor.

Something uses the electricity – ignition/ lights/ horn.

If you are experiencing suspected electrical problems these things need to be tested/ examined in isolation to determine the cause.

These get bad wrap from some people but we sell at least two analogue kits for British twins every week and have honestly not had a genuine warranty claim in the last 3 years. We do get some back which are thought to be faulty but they invariably test OK on our test bench.

I have some suggested tests if problems are experience.

Disconnect the black/yellow and black/white wires up near the black box. Test the resistance down the wires through the pick up unit. Should read 135 ohms +/- 5%. While doing this, have someone wiggle the wires inside the timing cover – occasionally the wire can break inside the sheathing.

Remove the black wire from the first coil. Place one lead to the ohmmeter on the coil where the black lead was attached and place the other on the positive (assume the bike is wired positive ground) terminal of the battery. With 6 volt coils you should read 4 ohms approx.

Commando owners – make sure the white wire to the black box is getting a full 12 volts. Later models used a ballast resistor, which must be removed, to lower the voltage to the coils to 6 volts. Also there must be a good ground between the motor and the frame. The motor is rubber mounted so there must be a separate ground wire connected to it.

Customer noticed his oil is milky in colour. This is most probably because of water and the oil needs changing immediately. When I used a British bike as a daily rider and drained the oil tank before warming up the motor, water would always run out before the oil. I know you should always warm up a motor before changing the oil but I am mentioning this just to illustrate how much moisture accumulates, especially on the inside of the oil tank, every time it cools down.

A customer who is a petrochemical engineer also told me once that especially, if you are on a long road trip, you should always fill up the gas tank at the end of the day – this will stop moisture building up due to the heat from the exhaust under the vehicle.

Here’s 2 questions we get asked almost every day about part numbers which can’t be found in the parts books.

Norton Twin Rocker Feed sealing washers (6) required. Part no is T1084 (06-7522). They are shown in the parts books in the Timing Cover section.

Triumph Gas Line Assemblies. – They are shown on the Carb diagrams.

Strictly speaking a bike should be registered by the frame number, although we see numerous bikes both in Canada and the USA which were registered before the mid 1980’s by the engine number. After that time the government obtained records from the vehicle manufacturers in their computer system of all vehicles imported. Before then they registered them by whatever number the dealer gave them at the time of sale. That is why so many vehicles are registered by the wrong year because they just registered them by the year they were actually sold.

This causes a lot of confusion because customers get wrong parts or parts which don’t fit because they are using the wrong parts books. It is essential to use the engine and frame numbers to make sure you get the correct parts books.

Also, vehicle model years run from August to July, not January to December. We frequently see, for example 1970 models, registered as 1969 models, because they were sold in the fall of 1969.

The parts book does not show the improved “wedding band” sealing assembly for the push rod tubes yet it was installed on most bikes. The reason is that the parts book was published in September 1969 and that the modification commenced in November of that year.

We just came across the following Service Bulletin, which owners of these bikes might find interesting.